Manufacturing

MRP + Maintenance + PLM + Quality

Manufacturing Reinvented

Manufacturing Reinvented

All you need in a single software

Easy + Powerful = Valuable

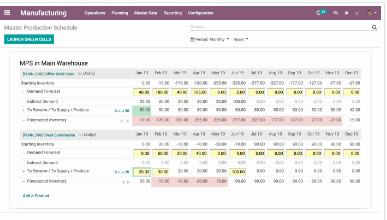

Optimize your inventory level

Through accurate fulfillment propositions.

Use make-to-order rules, minimum stock rules or the master production schedule to automate procurements. Let the scheduler compute everything for you. Use routes, constraints and lead time to optimize inventory level and avoid shortages.

Barcodes,

out-of-the-box

Whether you use lots, serial numbers or unidentified products, you can use barcodes to speed up operations at every step:

- Reception control

- Picking

- Packing

- Work orders

- ...and more!

Great Reporting & KPIs

All the data you need at your fingertips.

Control your productivity with real-time Overall Equipment Efficiency (OEE) reports and monitor the 6 big losses of TPM. Track maintenance KPIs like MTTR and MTBF. Create customized dashboards to monitor performance in real time.

Dynamic reports on everything from costing to traceability, performance analysis, OEE, and more help you make smarter decisions about your business.

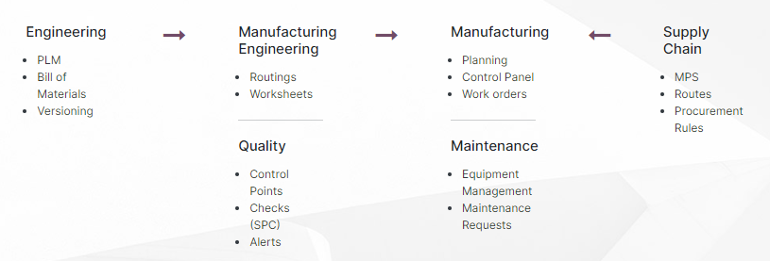

Key Features

Bill of materials

Create and manage BOM's for finished products, assemblies and sub assemblies.

Capacity Planning

Plan and schedule production based on capacity and resource availability, including machines, labor and materials.

Quality Control

Implement quality control procedures to ensure product quality and compliance with industry standards.

Routing

Define and manage manufacturing routings for different products, including work centers, operations and work orders.

Work Order

Create and manage work orders for different production stages, including manufacturing, quality control and packaging.

Inventory management

Manage inventory levels and track stock movement from the time of production until the product is sold.

Shop floor control

Monitor and manage manufacturing operations on the shop floor, including work orders, machine and labor.

Material Requirements Planning

Use MRP to forecast demand, plan production, and optimize inventory levels.

Product Lifecycle Management (PLM)

Manage the entire lifecycle of your products, from design to production to delivery.

Maintenance Management

Schedule and track maintenance activities for machines and equipment to prevent downtime and improve productivity.

Production Analysis

Analyze your production performance by product, work center, shift, and operator, and identify areas for improvement.

Quality Alerts

Manage quality alerts to quickly respond to quality issues and prevent defects.

Work Center Management

Manage work centers and their associated resources, including machines, labor, and materials.

Mobile Access

Access Odoo Manufacturing module from your mobile device to manage your production processes on the go.

Integrations

Integrate with other Odoo modules, such as Inventory, Accounting, and Sales, to streamline your business processes.